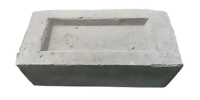

We take pride in offering premium quality Fly Ash Bricks...

Read More© 2025 ICBC Power Bricks. Created for free using WordPress and Kubio

All Bricks and Block Production

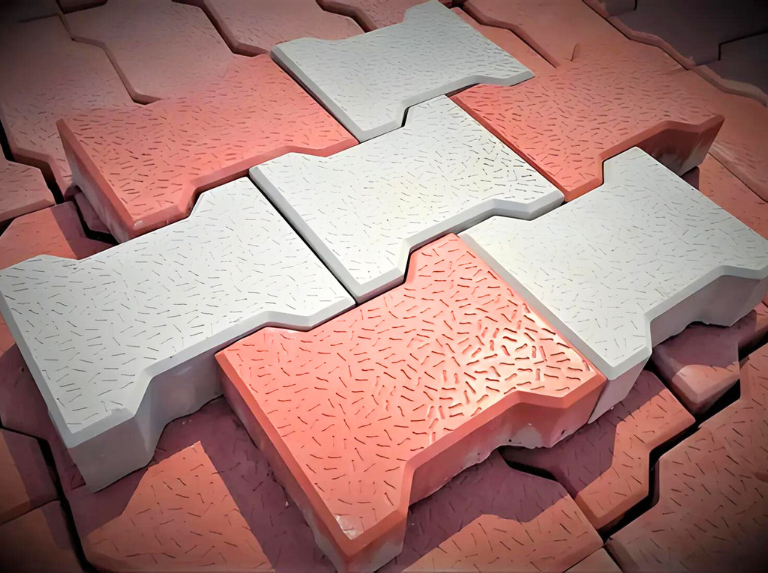

UNI Paver Blocks

We offer high-quality UNI Paver Blocks that provide both aesthetic...

Read MoreI Shape Paver Blocks

We manufacture high-quality I Shape Paver Blocks designed for strength,...

Read MoreKerb Stones

We manufacture high-quality Kerb Stones designed for defining boundaries and...

Read MoreHollow Concrete Blocks

We specialize in manufacturing high-quality Hollow Concrete Blocks designed for...

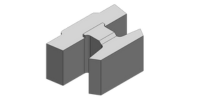

Read MoreRetain Blocks

We offer premium Retain Blocks designed to provide excellent support...

Read MoreAbout ICBC Power Bricks

At Indian Cement Bricks Company (ICBC), we offer Bricks, engineered for exceptional strength, durability, and performance. These high-density bricks are made from premium materials, providing superior load-bearing capacity and excellent weather resistance. Perfect for both residential and commercial construction, ICBC Power Bricks ensure long-lasting structural integrity while maintaining energy efficiency through enhanced thermal insulation. Their uniform shape and size allow for faster construction, reducing labor costs and time. Designed to meet the demands of modern building standards, ICBC Power Bricks offer reliability, durability, and sustainability in every project. Build with confidence—build with ICBC Power Bricks.

Our Services

Fully automatic operation implies that the machine can perform its functions with minimal human intervention. This often includes automatic feeding of raw materials, automated mixing, molding, and stacking of finished products.

Fly ash is a byproduct of coal combustion and is commonly used in the production of bricks and blocks. It is known for its poolanic properties, which contribute to the strength and durability of the final products

This indicates the machine’s production capacity over an 8- hour period. The specified range suggests that the machine can produce between 13,000 and 15,360 bricks in that time frame. The actual capacity may depend on factors such as machine design, raw material composition, and operating conditions

For stacking the finished products in an organized manner. It’s important to note that the specific features and components can vary between different models and manufacturers. f you’re considering purchasing or using such a machine, it’s advisable to refer to the manufacturer’s documentation for detailed specifications and operating instructions.

Where the formed bricks or blocks are allowed to cure and dry.

Hopper and Conveyor System : For feeding raw materials into the machine. Mixing Unit: Where materials like fly ash, cement, sand, and waterare mixed to form a homogenous mixture. Molding Unit: Shapes the mixture into bricks or blocks. Hydraulic System: Often used for applying pressure to the molds to form compact and sturdy bricks or blocks.

Team Of Experts

Mark Adam

Solar Engineer

Jhon Wilson

CEO

Lio Farnandes

Solar Technician

“We’ve been using ICBC Power Bricks for several of our construction projects, and the results have been outstanding. The strength and durability of these bricks are unmatched, and they’ve significantly reduced our construction time. The uniformity and precision in design make installation much easier, and the thermal insulation properties have been a huge bonus. We highly recommend Indian Cement Bricks Company for any building material needs. They consistently deliver top-notch products that meet modern construction standards!”

Rajesh Kumar, Project Manager

at RK Constructions

All Brick & Block Production Capacity With Sizes

Fly Ash Brick

230 X 110 X 75 MM

9 X 4 X 3

250 X 125 X 75 MM

10 X 5 X 3

Uni Paver Block

225 X 112.5 X 60 / 80 MM

I Shape Paver Block

200 X 160 X 60 / 80 MM

Retain Block

450 X 300 X 190

Solid Concrete Block

400 X 200 X 200 MM

(16" X 8" X 8" INCH)

Hollow Concrete

390 X 190 X 190 MM

Hollow Block

390 X 190 X 190 MM

Kerb Stone

380 X 250 X 100